Hebei Xinda Steel Group Co., LTD. (referred to as Hebei Xinda Steel Group) was founded in 2002 and is located in Qian 'an Economic Development Zone, Hebei Province. It is a large-scale national steel enterprise group integrating sintering, ironmaking, steelmaking, steel rolling, oxygen production, power generation, sewage treatment, and solid waste resource utilization. It currently has 7,350 employees. For many consecutive years, it has been listed on the "Top 500 Chinese Enterprises", "Top 500 Chinese Private Enterprises" and "Top 500 Chinese Manufacturing Enterprises", ranking 9th among the top 100 private enterprises in Hebei Province and 8th among the top 100 private manufacturing enterprises in Hebei Province. It has been awarded the titles of National Advanced Collective in the Steel Industry, National Green Factory, National AAA-level Tourist Attraction, and Advanced Intelligent Factory of Hebei Province. It is A national High-tech enterprise, a single champion enterprise in the manufacturing industry of Hebei Province, and one of the first steel enterprises in Hebei Province to pass the re-evaluation of environmental performance A-level enterprises.

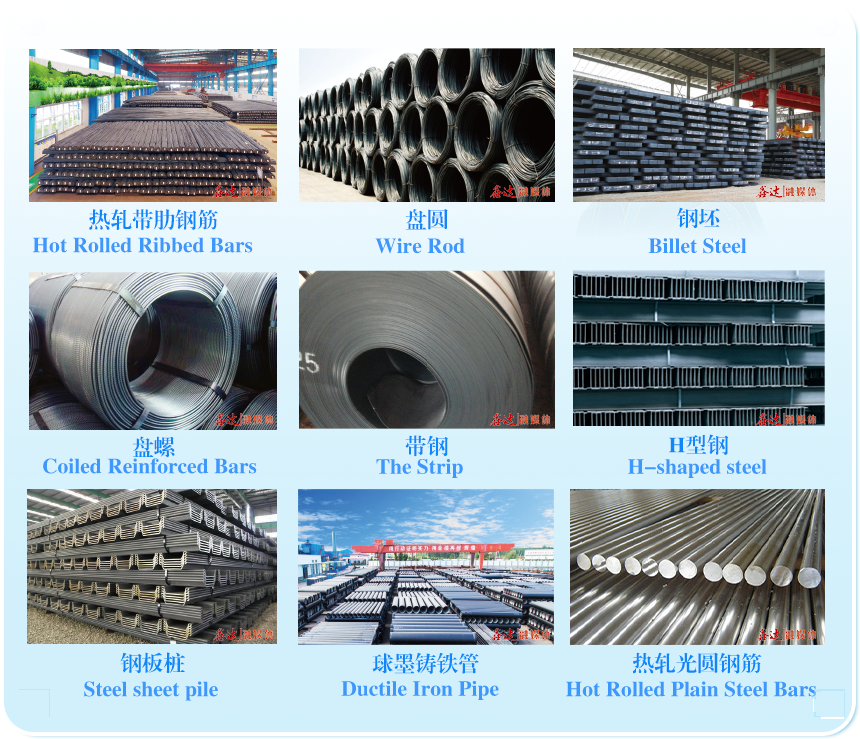

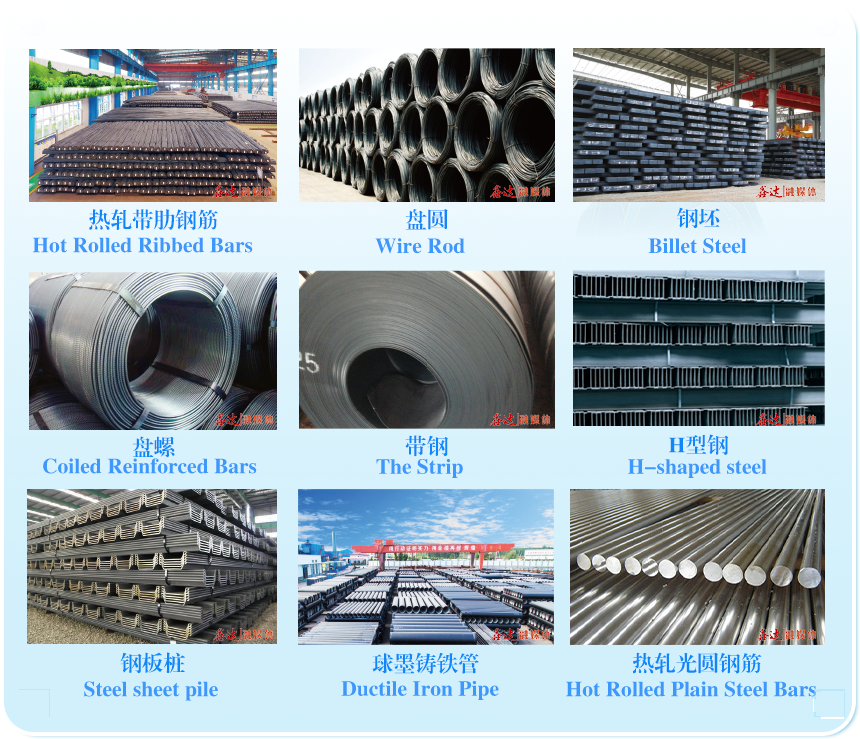

Main products

Product application

The company's main products include seismic threaded steel, high-strength H-beams, hot-rolled coil plates, high-quality strip steel, etc., which are widely used in construction machinery, high-speed rail, automobiles, home appliances, construction, Bridges and other fields, and are sold to 27 countries and regions around the world. Adhere unwaveringly to the development concept of "innovation, green development, openness and win-win", always take the real economy as the foundation, scientific and technological innovation as the lead, and industrial upgrading as the direction, and vigorously develop advanced productive forces that are high-end, intelligent and green. It has established a national CNAS-accredited quality inspection center, a Hebei Provincial enterprise technology center and other R&D platforms, and has cumulatively obtained over 600 independent intellectual property rights. Our series of products have obtained the "National Industrial Product Production License", ISO9001 system certification, South Korea KS certification, and National Metallurgical Product MC certification. We have been approved as the designated steel bar production enterprise in Xiongan New Area, received the "Golden Cup Quality Product" award from the China Iron and Steel Association, and won the "Mayor's Quality Award of Qian 'an City".

Green development

As a firm advocate and benchmark practitioner of the concept that "green mountains and clear waters are as valuable as mountains of gold and silver", Hebei Xinda Steel Group has always adhered to land intensification, harmless raw materials, clean production, waste resource utilization, and low-carbon energy. It has cumulatively invested 5.98 billion yuan to promote ultra-low emission transformation and ecological environment protection in a coordinated manner. Advanced organized emission reduction equipment such as SDS dry desulfurization, SCR denitrification and LT dry dust removal processes have been introduced. All material yards have been equipped with fully mechanized and enclosed material sheds, and intelligent dry fog dust suppression systems have been installed at key dust-generating points. A long-distance transportation system for bulk goods has been successfully established, mainly featuring the largest inland dry port and dedicated railway lines in North China, as well as a short-distance transportation system dominated by hydrogen energy vehicles and pure electric tractors. The proportion of new energy vehicles in clean transportation methods exceeds 80%. Committed to building a "resource-conserving and environment-friendly" manufacturing enterprise, we have implemented projects for the recycling and utilization of gas, steam and industrial wastewater. The self-generated electricity rate has reached 75%, and 100% of production and domestic wastewater has been recycled. The waste heat from water sludge is used for centralized heating in the surrounding communities. The industrial solid waste resource utilization plant has an annual production capacity of 3 million tons of slag micro-powder, 700,000 tons of particle steel hot-formed briquettes, and processes 2 million tons of steel slag. It aims to achieve pollution reduction and carbon emission reduction, as well as synergistic efficiency improvement, and strives to build a leading enterprise in green development.

Technological steel

Implement the strategic layout of "Steel Technology · Technology Steel", and build an "8+2+1" intelligent manufacturing system architecture with 8 major business systems such as MES production management and execution system and ERP financial management system, as well as process big data pool, business big data pool and 1 intelligent manufacturing demonstration production line as the main body. Fourteen intelligent mechanical arms, including the automatic temperature measurement and sampling system for molten iron ladles, the intelligent platform system for continuous casting, the unmanned platform system for large ladles, the robot billet marking system, and the automatic slag feeding system for mechanical hands, have been put into use. More than ten sets of intelligent automation systems, such as the surface quality inspection system for section steel and the steel leakage prediction system for slab continuous casting machines, The unmanned continuous casting platform has achieved a global first in the industry by simultaneously replacing the long nozzle with two robots. The company actively promotes the intelligence of its industries and the industrialization of intelligence. Through an industrial Internet intelligent platform and AI large models, it achieves intelligent operation and remote dispatching. It independently develops an intelligent optimization combustion system for hot blast stoves, which enables the stoves to burn more efficiently, economically and intelligently with precise control. This can achieve an annual cost reduction of 23.193 million yuan, adding strong impetus to the high-quality development of the enterprise.

Looking forward to the future

Ambition transcends mountains and seas; the collective will comprehends a new chapter. Hebei Xinda Steel Group Co., Ltd. will anchor on the cutting-edge of science and technology, be bold in exploration and experimentation, stand at the forefront of the market and forge ahead through waves, strive for excellence in quality, drive the growth momentum to a vigorous leap towards innovation-driven, promote the industrial value to a strong leap towards high added value, and lead the industrial structure to a comprehensive breakthrough towards high-end! Fully implement the business policy of "Lean operation and ultimate efficiency creation", be an enterprising "dream builder" and an "dream realizer" looking up at the stars, march with resounding steps, ride the favorable wind of the new era, and with an energetic posture, paint the future, and inject the "Xinda power" into the vigorous modernization of China!

Email

Email Email

Email